Every woodworker needs a mallet. I had 3/4″ oak boards that I got on clearance at the big box store because they were warped. I find these kinds of boards are useful for small projects where I can mill away enough to straight it, or for things like end-grain cutting boards since it will all get cut up into such small pieces, the warp doesn’t matter.

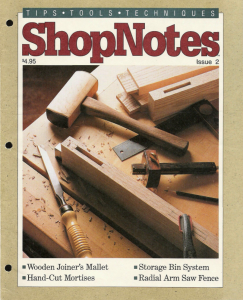

With respect to design, I looked around a lot and saw many joiner’s mallets that were turned out of either solid, or glued up blocks of wood. Unfortunately, while I have a lathe, I’m not much of a turner yet. Instead, I went with a design I’d seen many others use. Its originally (as far as I can trace), from ShopNotes Magazine. The design is four main peices. The handle is cut from a long peice, with a tennon on the end. The middle has two large holes drilled in it to be filled with BBs or lead shot. I had neither, and used dozens of small screws. These had the desired dead-blow effect. Finally, two end peices cover up the holes and seal in the metal contents. I did the rough shaping with the table saw and then moved onto the sander for final shaping. It was far from perfect, but a little wood glue and sawdust filled in some imperfections. I did a nice cherry stain on the oak, and finished it with mineral oil and paste wax. Some contact cement keeps on two pieces of thick brown leather to keep from marring the pieces this mallet is used on.

With respect to design, I looked around a lot and saw many joiner’s mallets that were turned out of either solid, or glued up blocks of wood. Unfortunately, while I have a lathe, I’m not much of a turner yet. Instead, I went with a design I’d seen many others use. Its originally (as far as I can trace), from ShopNotes Magazine. The design is four main peices. The handle is cut from a long peice, with a tennon on the end. The middle has two large holes drilled in it to be filled with BBs or lead shot. I had neither, and used dozens of small screws. These had the desired dead-blow effect. Finally, two end peices cover up the holes and seal in the metal contents. I did the rough shaping with the table saw and then moved onto the sander for final shaping. It was far from perfect, but a little wood glue and sawdust filled in some imperfections. I did a nice cherry stain on the oak, and finished it with mineral oil and paste wax. Some contact cement keeps on two pieces of thick brown leather to keep from marring the pieces this mallet is used on.